A Basic Troubleshooting Guide For Espresso Machines

We are mostly talking about Commercial Machines although some good practice applies also to Domestic Machines.

Cleaning

It is a fact that more problems are caused by poor cleaning than actual machine failure so a simple daily routine will help the machine, along with keeping up the quality of coffee.

Filter Basket

Clean daily in hot water. Common practice is to soak filter baskets in hot water and a detergent, such as Puly Caff overnight to dissolve deposits.

Grouphead

Clean daily, in the morning. Place a teaspoon of Grouphead Cleaner such as Puly Caff into a Blind Filter Basket in your portafilter. Attach the portafilter to the group. Run the coffee delivery switch for approx. 10 seconds, stop for a few seconds and run again. Do this 4 times. Remove the Portafilter and rinse then put back on the machine and run the coffee delivery switch for 10 seconds, stop take the Portafilter off and rinse and repeat this 4 times. It also helps to do this ‘Back Flushing’ throughout the day without the detergent.

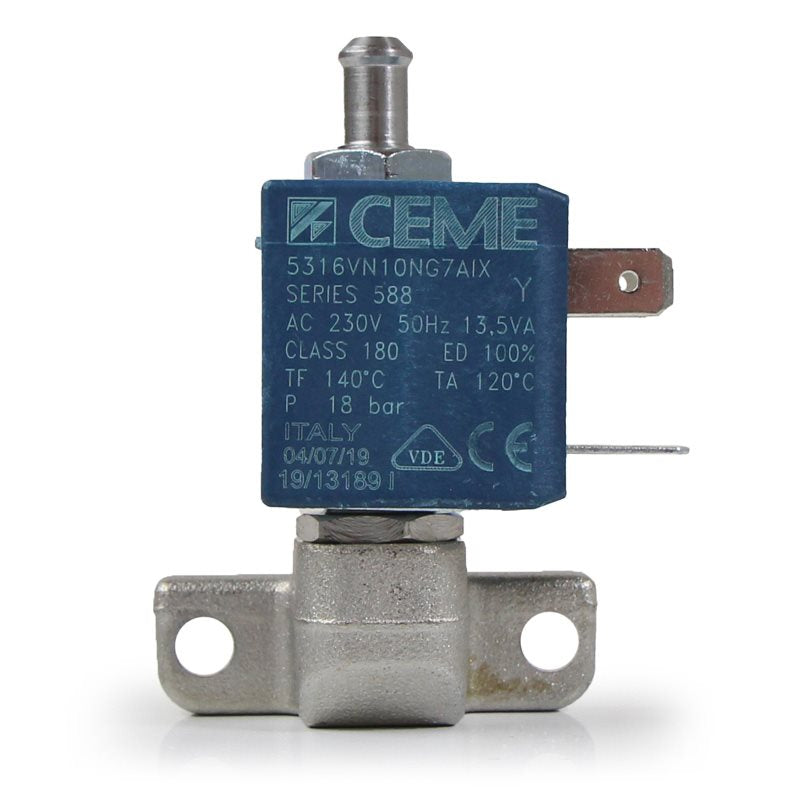

Perform this operation only if your machine is equipped with a 3-way Solenoid Valve that allows Back-Flushing from the Portafilter though the Grouphead to the Drip Tray. Basically you cannot backflush machines unless it has the equivalent of an E61 grouphead.

Steam Nozzles

Steam Nozzles should be kept clean at all times. When frothing milk wipe the Steam Wand with a Clean Damp Cloth, when finished, purge the wand with a blast of steam to clear any milk in the Tip. If you notice not all steam jets working use a paper clip to clear short term but remove the tip and clean with a detergent such as Puly Milk when possible.

Water Softener

If you have hard water in your area then a proprietary water filter must be installed. Scale build-up in coffee machines is a costly problem and replacing filters on a regular basis in line with the volume of water you are using is essential.

Troubleshooting Guide

| Problem | Possible Cause | Possible Solution |

| No power to machine | On/Off switch is in wrong position | Many machines have power switches that can be in more than one position. Usually a light will indicate when power to the element is activated. |

| Fuse has blown in the power supply to the machine | Several parts of a machine can contribute to tripping the electrics. A loop in the element or a coil of an electrovalve are favourites. | |

| Safety thermal switch on the machine has tripped | Not all but many machines have a safety cut-out that will trip if the machine overheats. More common on domestic machines but also on many commercials. | |

| Machine not dispensing coffee or dispensing very slowly | Coffee grind too fine or packed too tightly to allow water through the basket | Take the handle off and press to make a coffee if water runs ok then the coffee grind has been set too fine or the handle is blocked and needs cleaned. |

| Problem with water supply | Check mains water supply not turned off or Water filter blocked. | |

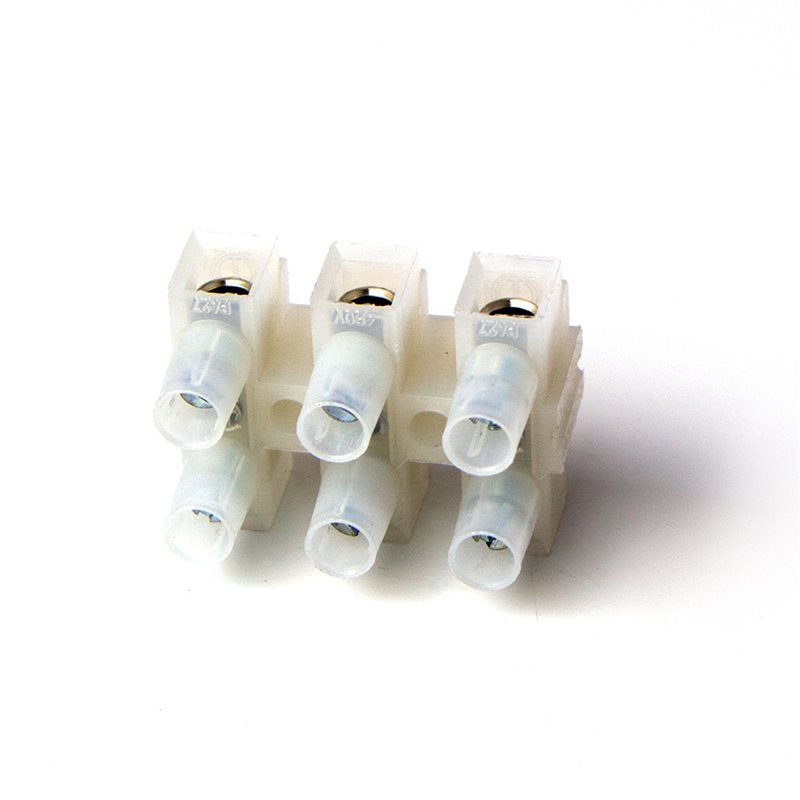

| Electrovalve for water supply not operating | It is not uncommon for dirt in the water supply to jam the valve that opens to allow water into the machine. | |

| Problem with pump | Pumps and pumpheads fail on a regular basis you can usually tell by the noise the pump is making if the problem is here. | |

| Grouphead blocked with scale | On a domestic machine running a descale solution into the boiler may help. For commercials the jets in the grouphead will probably need removed and cleaned. | |

| Group solenoid valve not operating | If when you press the button to make a coffee you hear a click but no water appears then the electrovalve has failed to open and will probably need taken apart and cleaned. | |

| Lack of cleaning | Coffee is very oily and this oil builds up in the grouphead, in the baskets and in the portafilter. Clean all parts that come into contact with the coffee on a regular basis with a degreaser such as Puly Caff. | |

| Coffee dispenses too quickly | Coffee grind is too coarse. | Adjust your grinder to make the coffee grains finer. Do not use coffee that has been lying and dried out. |

| Coffee leaks over the side of the portafilter and coffee grains land in the cup | Not using a brush to clean the group seal | When making coffee it is important to knock any loose grains off the rim of the basket before putting on the machine otherwise it will not seal properly. |

| The filter baskets are old and dented from hitting off a hard surface | Replace dented filter baskets they will not hold the pressure generated by the machine. | |

| The group seals are old and worn and need replaced | Group seals should be replaced at least once per year. Seals harden over time due to being continually compressed and operating at a high temperature. | |

| Dirty water found under the machine | Blocked drain hose or outlet from drain bowl | If the drain hose is into a standpipe make sure the end of the hose is not jammed in preventing drainage. If into a bucket the end of the hose should not be in the water. It is good practice to pour a solution of dissolved Puly Caff degreaser into the drip tray. |

| Clean water found under the machine | Leak from anywhere | There are so many pipes carrying steam and water round a machine to identify where the problem lies it will be necessary to remove the top from the machine. |

| No hot water or steam | Machine has not come up to operating pressure | Your machine will not dispense steam or hot water until there is sufficient pressure in the hot water boiler. If there is hot water and no steam then check the nozzle is not blocked with milk. |

| Water comes out of steam nozzle | Boiler has overfilled | If the machine does not detect the level of water in the boiler it will overfill and overflow. Common problem is scale or dirt build-up on the level probe. |

The above are just a few general pointers to common problems with espresso coffee machines. Many problems can be addressed by the operator but others will require a local coffee machine engineer.